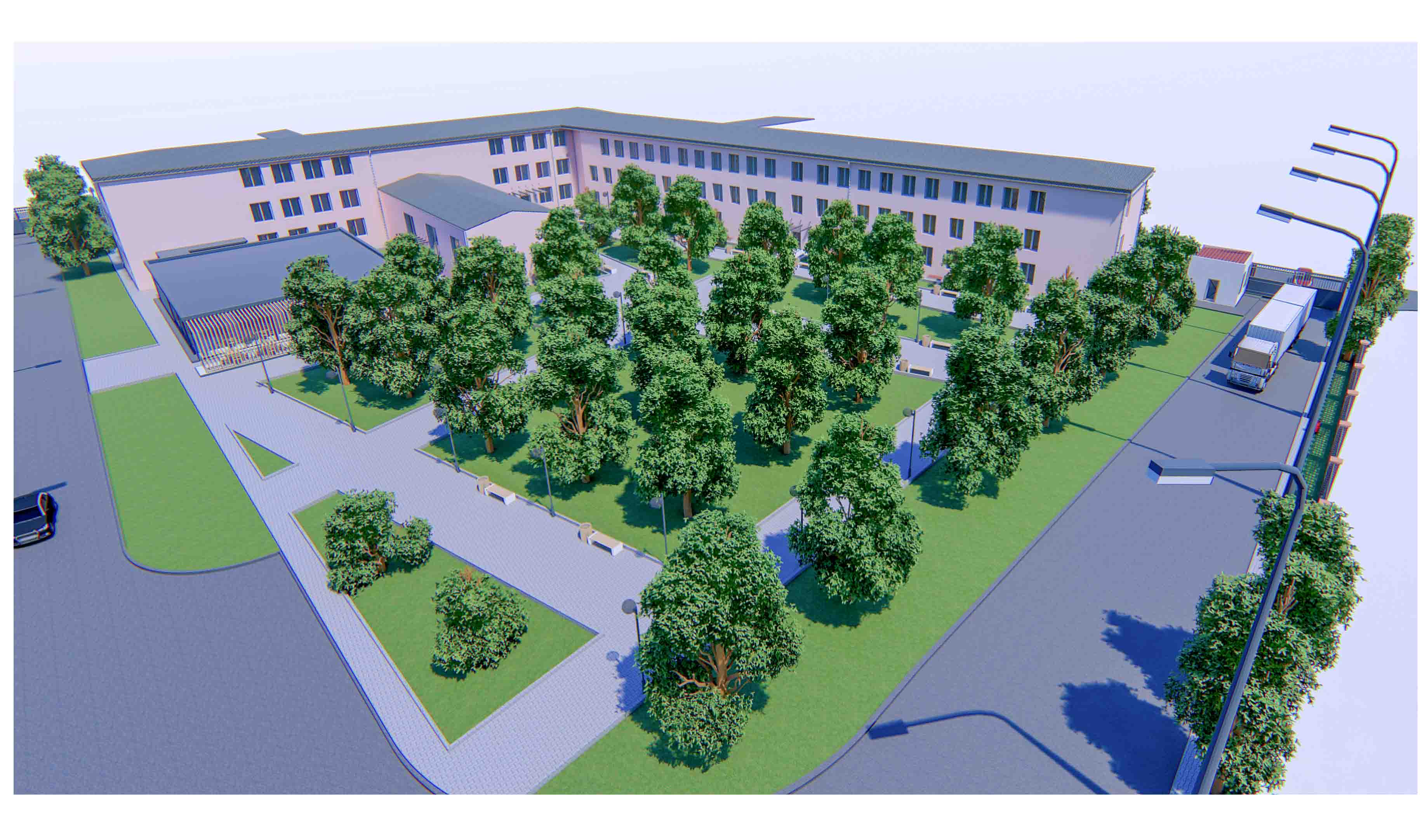

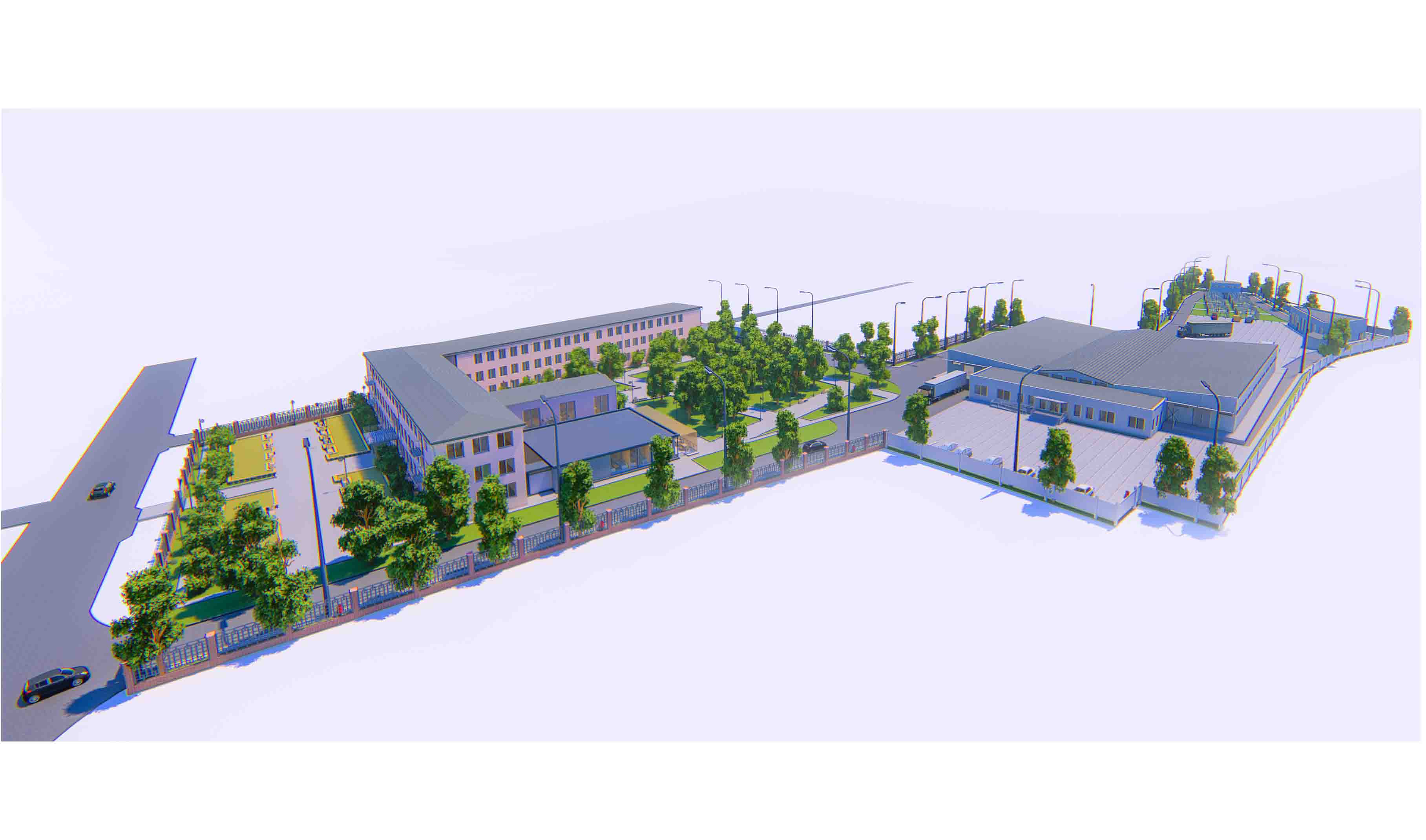

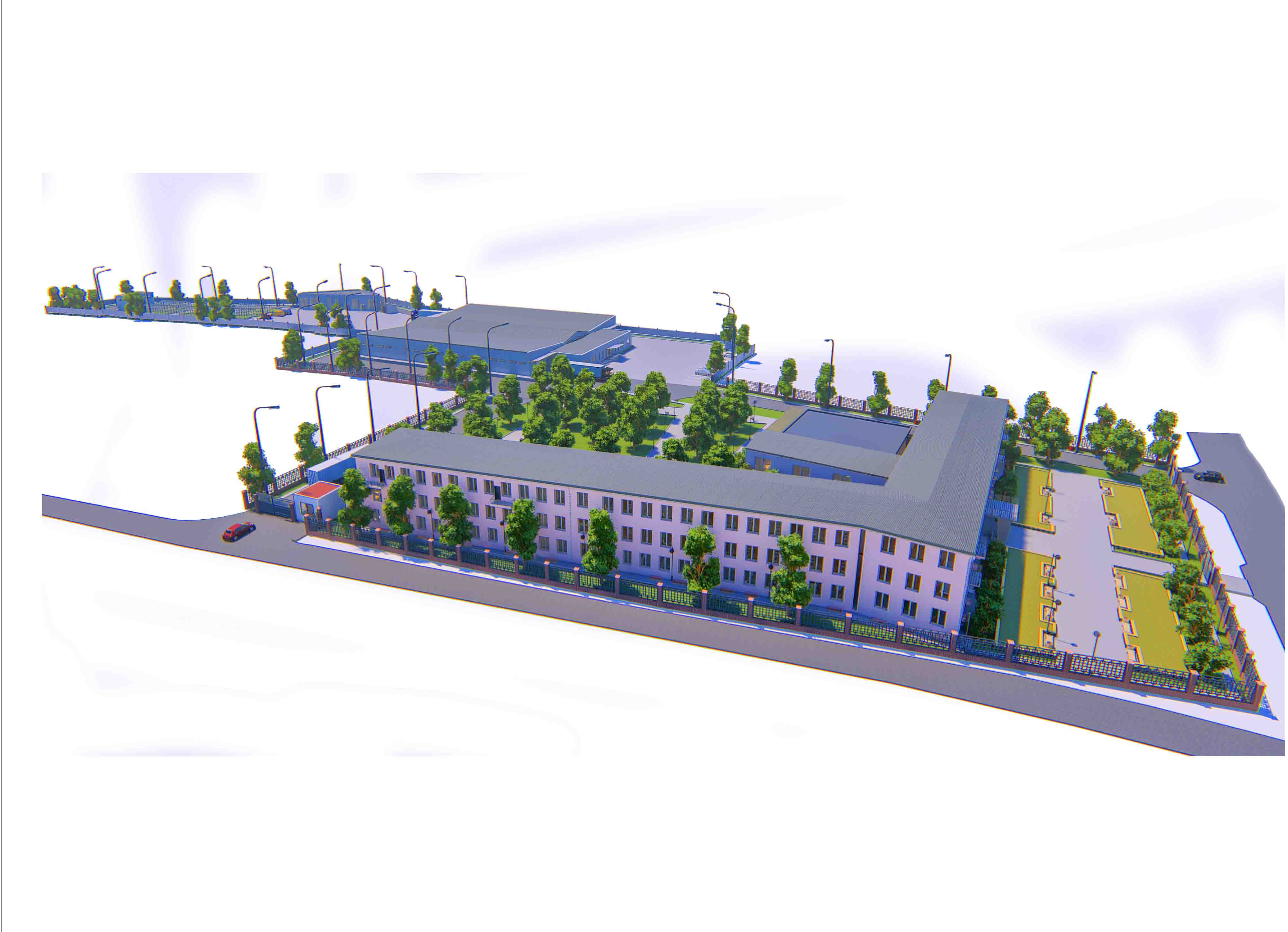

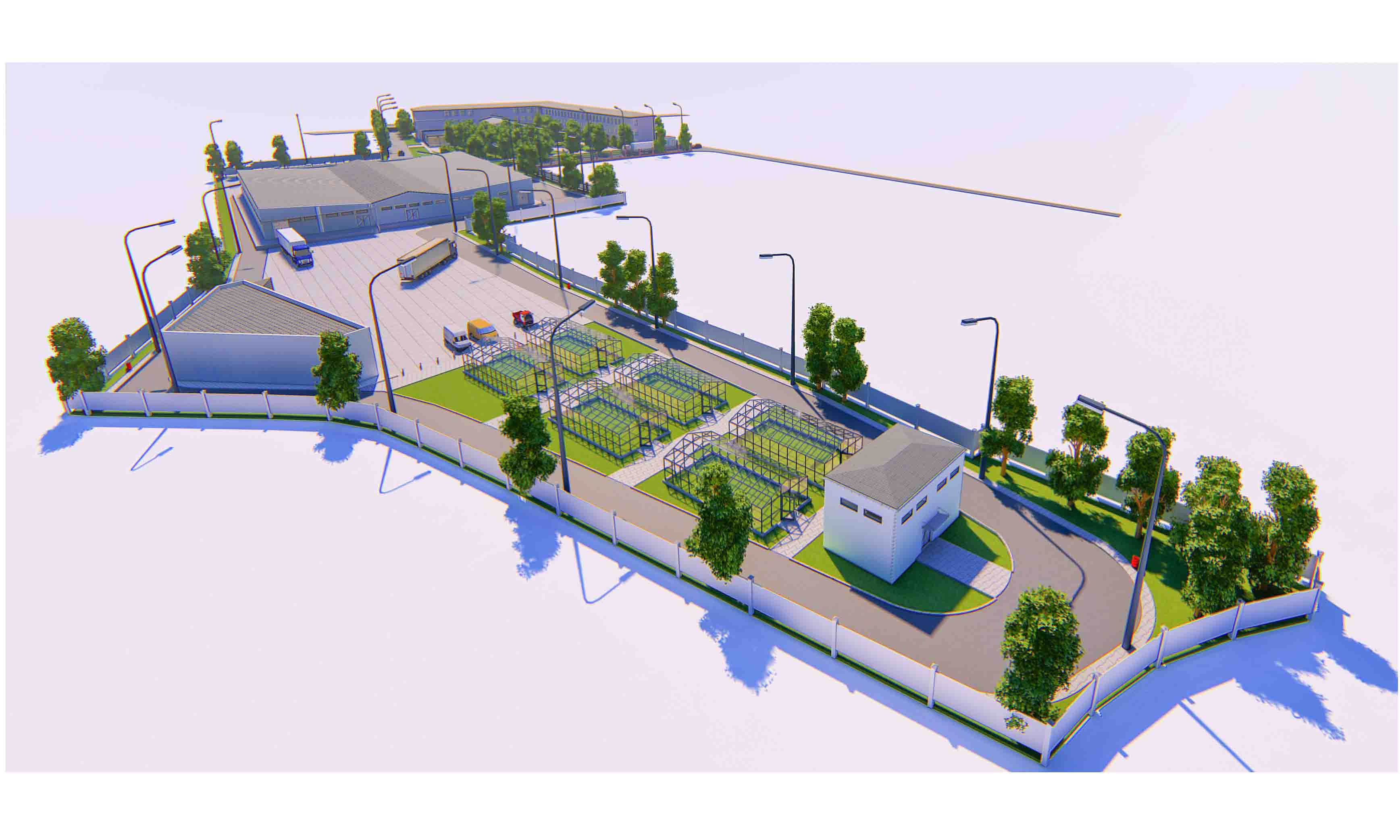

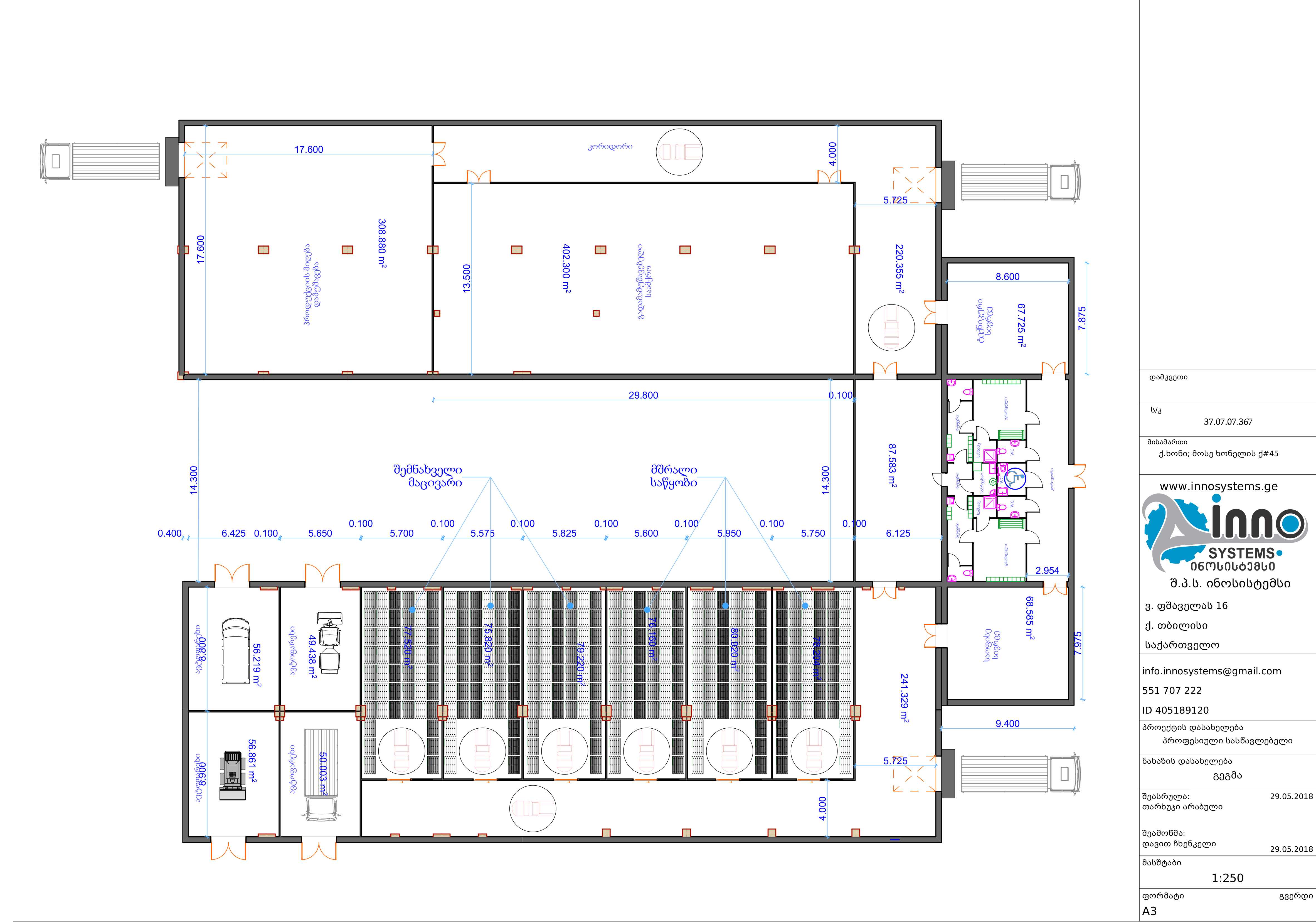

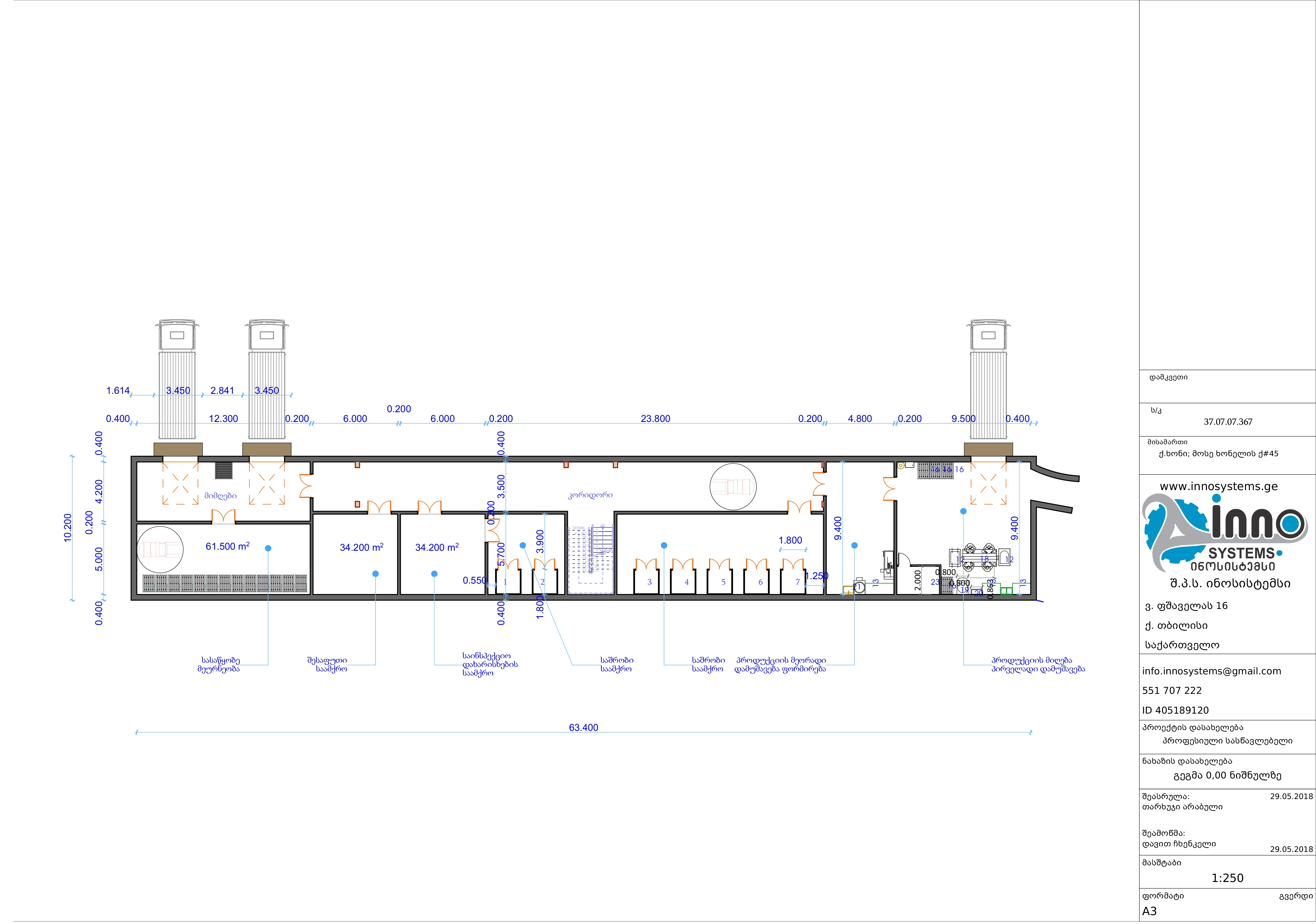

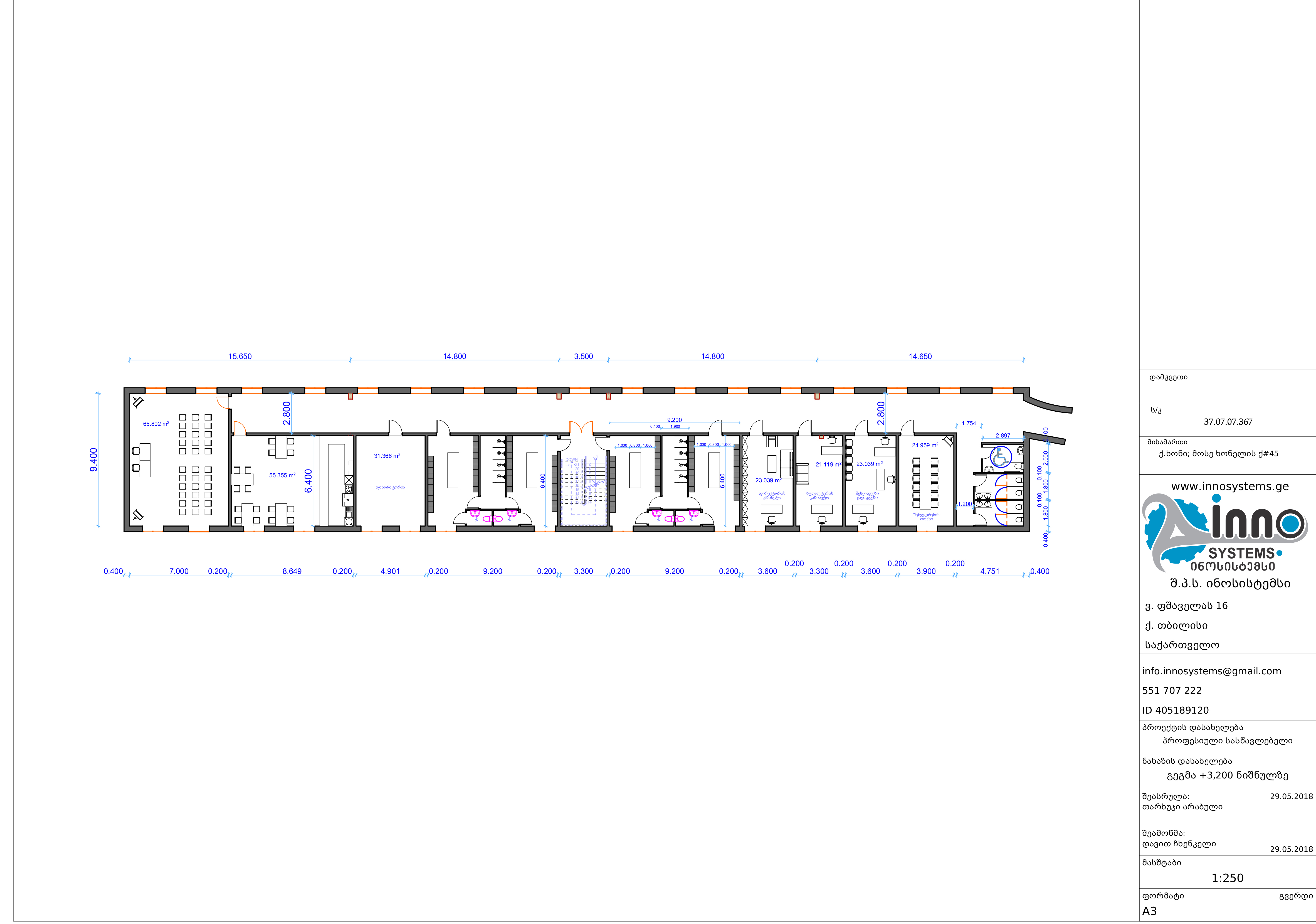

Professional School in Khoni

Customer: "Employers' Association

The project was ordered on July 20, 2018

The project is completed on September 20, 2018

The subject of the order is to develop the conceptual project of the Khoni College Enterprise Interactive Center.

The company "Innosystem" LLC has implemented the relevant works by the professional team of the respective sector for the project of the project as a conceptual project of the Khoni College Enterprise Interconnection Center, which has received a positive assessment and the client is looking for a reliable investor to carry out this project.